Rice Processing Machinery India Market Trends and Growth Forecast

As Per Market Research Future, the Rice Processing Machinery India segment focuses on equipment specifically designed for the processing of rice, including milling, sorting, and packaging. These machines are essential for ensuring high-quality rice production and minimizing post-harvest losses. The demand for rice processing machinery in India is driven by the increasing focus on improving agricultural productivity and the need for modernized milling techniques. As advancements in machinery technology continue to evolve, this segment is projected to grow significantly, reflecting ongoing trends in rice processing.

Rice processing machinery plays a crucial role in transforming harvested paddy into edible rice, supporting one of the most important food supply chains in India. As one of the world’s largest producers and consumers of rice, the country relies heavily on efficient milling and processing infrastructure to meet domestic demand and sustain export markets. Traditional manual methods have gradually been replaced by mechanized systems that improve productivity, reduce waste, and enhance grain quality. This transition reflects broader agricultural modernization efforts aimed at strengthening food security and rural livelihoods.

The rice processing cycle involves several stages, including cleaning, dehusking, paddy separation, whitening, polishing, grading, and packaging. Each stage requires specialized machinery designed to handle large volumes while preserving grain integrity. Modern rice mills employ automated equipment capable of processing tons of paddy per hour with minimal human intervention. Advanced sensors and control systems monitor moisture levels, temperature, and milling pressure to ensure consistent output quality. Such precision is essential because even small variations can affect taste, appearance, and market value.

One of the primary benefits of mechanized rice processing is the reduction of post-harvest losses. In traditional systems, improper handling and inefficient milling often result in broken grains and wasted byproducts. Modern machinery minimizes these losses through optimized processing techniques and improved material handling. Additionally, byproducts such as husk and bran can be utilized for energy generation, animal feed, or value-added products, creating additional revenue streams for mill operators.

Government initiatives and agricultural policies have encouraged the adoption of advanced rice processing equipment across rural regions. Subsidies, training programs, and financial support mechanisms help small and medium-scale millers upgrade their facilities. These efforts aim to increase efficiency, improve farmers’ incomes, and enhance competitiveness in global markets. Export-oriented processing requires strict quality standards, making modern machinery indispensable for meeting international specifications.

Technological advancements are reshaping the industry further. Computerized control systems enable real-time monitoring of operations, while automated sorting machines use optical sensors to remove discolored or damaged grains. Energy-efficient motors and eco-friendly designs reduce operational costs and environmental impact. Some facilities are integrating renewable energy sources, such as biomass from rice husk, to power milling operations sustainably. This approach not only lowers energy expenses but also addresses waste management challenges.

Labor dynamics are also evolving as mechanization increases. While automation reduces the need for manual labor in certain tasks, it creates demand for skilled technicians capable of operating and maintaining sophisticated equipment. Training and education programs are therefore essential to ensure that the workforce can adapt to technological changes. The growth of agro-processing clusters and industrial zones is fostering knowledge sharing and innovation within the sector.

Despite progress, challenges remain. High initial investment costs can deter small millers from adopting advanced machinery, and inconsistent power supply in some regions can disrupt operations. Maintenance and spare parts availability also influence long-term sustainability. Addressing these issues requires coordinated efforts from government agencies, financial institutions, equipment manufacturers, and industry associations.

Looking forward, the rice processing machinery sector in India is poised for continued growth as demand for high-quality rice increases both domestically and internationally. Urbanization, changing dietary patterns, and expanding export opportunities will drive modernization across the value chain. Emerging technologies such as artificial intelligence, robotics, and Internet-of-Things-based monitoring systems may further enhance efficiency and traceability. By embracing innovation while supporting small producers, the industry can strengthen its role in ensuring food availability and economic stability.

FAQs

What is rice processing machinery used for?

It converts raw paddy into consumable rice through cleaning, milling, polishing, and grading processes.

How does modern machinery improve rice quality?

It reduces broken grains, ensures uniform polishing, and removes impurities more effectively than traditional methods.

Can small farmers benefit from advanced rice mills?

Yes, through cooperative models and government support programs, small producers can access improved processing facilities.

More Related Reports:

Categorías

Read More

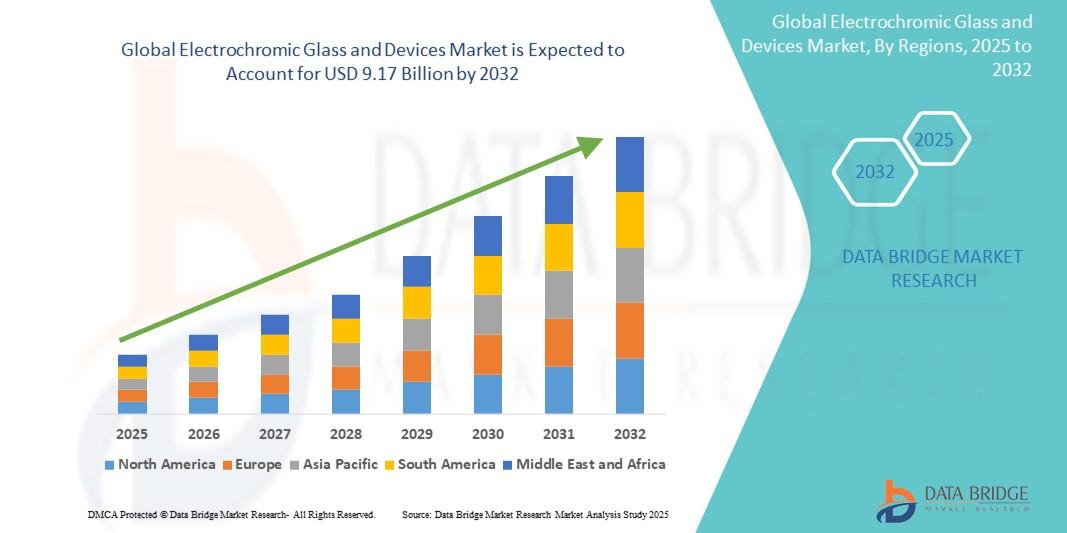

The Glass and Devices Market, a critical component of the construction, automotive, electronics, and packaging industries, is witnessing significant technological transformation. This market encompasses traditional glass manufacturing as well as advanced, high-performance materials like smart glass and ultra-thin display glass. The primary drivers are the surging demand for...

According to Straits Research, the global oil and gas accumulator market size was valued at USD 583.53 million in 2024 and is projected to reach USD 898.29 million by 2033, growing at a CAGR of 4.91% during the forecast period (2025-2033). The study draws from comprehensive primary interviews with industry experts, verified...

The Auto Extended Warranty Market has become an essential segment of the automotive industry, offering vehicle owners additional protection beyond the standard manufacturer warranty. As cars become increasingly sophisticated with advanced electronics, connectivity features, and complex powertrains, the risk of costly repairs has risen, creating a strong demand for extended...

Carbon and alloy steel tubes are critical for various applications, including structural and industrial uses. The demand for these tubes is rising due to their strength and versatility. The market for carbon and alloy steel tubes is anticipated to expand, driven by innovations in material science and the increasing focus on high-performance solutions in various industries. The seamless steel...

Healthcare Artificial Intelligence Market Accelerates as Data-Driven Care Redefines Modern Medicine Healthcare Artificial Intelligence Market is estimated to be valued in the multi-billion-dollar range in 2024 and is projected to expand at a strong double-digit growth rate over the forecast period, driven by the rapid digitalization of healthcare systems, growing volumes of medical data,...