Aluminum Welding Market Strengthens as Lightweight Manufacturing and EV Production Fuel Industrial Demand

"Comprehensive Outlook on Executive Summary Aluminum Welding Market Size and Share

CAGR Value

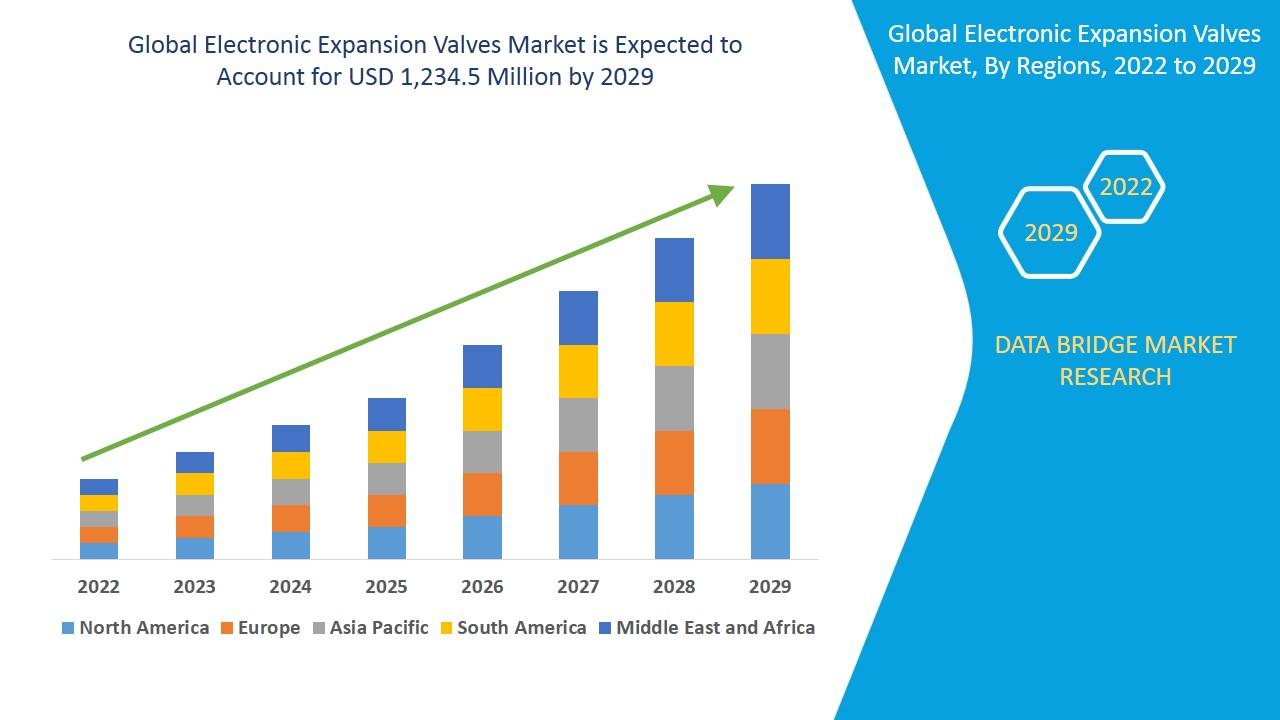

The global aluminum welding market size was valued at USD 4.47 billion in 2024 and is projected to reach USD 7.02 billion by 2032, with a CAGR of 5.80% during the forecast period of 2025 to 2032

For powerful business growth, companies must take up market research report service which has become quite vital in this rapidly altering marketplace. This Aluminum Welding report analyzes the market status, growth rate, future trends, market drivers, opportunities, challenges, entry barriers, risks, sales channels, and distributors. This report comprises of a deep knowledge and information on what the market’s definition, classifications, applications, and engagements and also explains the drivers and restraints of the market which is derived from SWOT analysis. Thus Global Aluminum Welding Market research analysis report serves a lot for your business and bestows you with solutions for the toughest business questions.

The detailed and comprehensive market study performed in this Aluminum Welding report offers the current and forthcoming opportunities to shed light on the future market investment. It consists of the most detailed market segmentation, thorough analysis of major market players, trends in consumer and supply chain dynamics, and insights about new geographical markets. Various parameters covered in this research report help businesses for better decision making. This Aluminum Welding Market research report encompasses different industry verticals for Aluminum Welding Market industry, such as company profile, contact details of the manufacturer, product specifications, geographical scope, production value, market structures, recent developments, revenue analysis, market shares, and possible sales volume of the company.

Access expert insights and data-driven projections in our detailed Aluminum Welding Market study. Download full report:

https://www.databridgemarketresearch.com/reports/global-aluminum-welding-market

Aluminum Welding Industry Snapshot

Segments

- By Welding Type: The global aluminum welding market can be segmented based on welding type into gas metal arc welding (GMAW), gas tungsten arc welding (GTAW), shielded metal arc welding (SMAW), and others. Each welding type has its own advantages and applications in different industries, contributing to the overall growth of the aluminum welding market.

- By Alloy Type: Aluminum welding can also be segmented by alloy type, including 1xxx series, 3xxx series, 5xxx series, 6xxx series, and others. The choice of alloy type is crucial in determining the strength, durability, and corrosion resistance of welded aluminum products, impacting the market demand for specific alloy types.

- By End-User Industry: The market can further be segmented by end-user industry, such as automotive, aerospace, construction, marine, and others. The demand for aluminum welding varies across these industries, with automotive and aerospace sectors witnessing significant growth due to the increasing use of lightweight materials for improved fuel efficiency and performance.

- By Region: Geographically, the global aluminum welding market can be segmented into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Each region has its own market dynamics, with Asia Pacific expected to dominate the market due to rising industrialization, infrastructure development, and technological advancements in countries like China and India.

Market Players

- Lincoln Electric Company: A key player in the global aluminum welding market, Lincoln Electric offers a wide range of welding solutions for various applications, including aluminum welding. The company's innovative technologies and strong market presence contribute to its leading position in the industry.

- Illinois Tool Works Inc.: Another prominent player in the market, Illinois Tool Works Inc. provides advanced aluminum welding equipment and solutions to meet the growing industry demands. The company's focus on research and development ensures high-quality products for its customers.

- ESAB: Known for its cutting-edge welding and cutting solutions, ESAB is a significant player in the aluminum welding market. The company's diversified product portfolio and global distribution network make it a preferred choice for customers worldwide.

- Air Liquide: As a leading provider of industrial gases and related services, Air Liquide plays a vital role in supporting the aluminum welding market with its specialty gases and welding expertise. The company's commitment to sustainability and innovation positions it as a key player in the industry.

The global aluminum welding market is characterized by intense competition, technological advancements, and a growing focus on sustainability and efficiency. Market players are continuously innovating to meet the evolving needs of customers across various industries, driving the overall growth of the market.

DDDDDThe global aluminum welding market is experiencing significant growth driven by various factors such as increasing demand across end-user industries, advancements in welding technologies, and the widespread adoption of lightweight materials like aluminum for improved performance and sustainability. One of the key trends shaping the market is the shift towards automated welding processes, enhancing efficiency, accuracy, and output quality. Automation in aluminum welding not only reduces labor costs but also ensures consistent results, making it a preferred choice for industries seeking higher productivity and precision.

Furthermore, the automotive and aerospace sectors are witnessing a surge in demand for aluminum welding solutions due to the emphasis on fuel efficiency, emission reduction, and overall performance improvement. As manufacturers strive to meet stringent regulatory standards and consumer preferences for lightweight yet durable materials, the need for advanced welding techniques and equipment continues to rise. This trend is expected to drive innovation and investment in the aluminum welding market, with players focusing on developing new solutions tailored to the specific requirements of these sectors.

In terms of regional dynamics, Asia Pacific stands out as a dominant market for aluminum welding, driven by rapid industrialization, infrastructural development, and the presence of key players in countries like China and India. The region's robust manufacturing sector, coupled with increasing investments in automotive and aerospace industries, is propelling the demand for aluminum welding technology. Moreover, the burgeoning construction and marine sectors in Asia Pacific are also contributing to market growth, creating opportunities for industry players to expand their presence and offer tailored solutions to meet diverse end-user needs.

Another aspect influencing the aluminum welding market is the emphasis on sustainability and eco-friendly practices. Companies are increasingly focusing on developing environmentally responsible welding processes, reducing waste generation, and optimizing energy efficiency in welding operations. This shift towards green manufacturing practices reflects changing consumer preferences, regulatory requirements, and industry initiatives aimed at reducing the carbon footprint of welding processes.

Overall, the global aluminum welding market is poised for continued expansion driven by technological innovation, diverse end-user applications, regional growth opportunities, and the industry's commitment to sustainability. Market players are expected to invest in research and development, strategic partnerships, and product differentiation to stay competitive and address evolving market demands. With a strong emphasis on quality, efficiency, and customer satisfaction, the aluminum welding market is set to witness further advancements and adoption across various industries, reshaping the landscape of welding technology in the years to come.The global aluminum welding market is undergoing a transformative phase driven by evolving industry trends and market dynamics. One notable aspect shaping the market landscape is the increasing adoption of automated welding processes. Automation is revolutionizing the welding industry by improving efficiency, precision, and productivity. With the use of robotics and advanced technologies, companies are able to achieve consistent and high-quality welds, reducing labor costs and enhancing overall output. The shift towards automation in aluminum welding is not only meeting the demand for faster production but also ensuring compliance with stringent quality standards in industries such as automotive, aerospace, and construction.

Moreover, the emphasis on lightweight materials like aluminum in the automotive and aerospace sectors is a key driver propelling the growth of the aluminum welding market. With a focus on fuel efficiency, emission reduction, and improved performance, manufacturers are increasingly turning to aluminum due to its strength-to-weight ratio and corrosion resistance properties. This trend is fueling the demand for advanced welding solutions tailored to the specific requirements of these industries. As a result, market players are investing in research and development to innovate new techniques and equipment that can meet the evolving needs of customers while ensuring the highest standards of quality and performance.

Regionally, Asia Pacific emerges as a pivotal market for aluminum welding, supported by robust industrialization, infrastructure development, and the presence of key industry players. Countries like China and India are witnessing significant growth in the manufacturing sector, driving the need for advanced welding technologies to cater to the rising demand for aluminum products. Additionally, the construction and marine sectors in the region are further contributing to market expansion, offering opportunities for market players to diversify their offerings and tap into new end-user segments. The dynamic growth in Asia Pacific underscores the region's importance as a key market for aluminum welding technology, with companies leveraging local expertise and strategic partnerships to drive innovation and meet the diverse needs of customers.

Furthermore, the industry's growing focus on sustainability and eco-friendly practices is influencing the development of environmentally responsible welding processes. Companies are aligning their operations with green manufacturing initiatives to reduce waste, optimize energy efficiency, and minimize the environmental impact of welding activities. This shift towards sustainable practices not only reflects changing consumer preferences but also aligns with regulatory mandates aimed at promoting cleaner production methods. By investing in eco-friendly welding solutions, market players are not only meeting regulatory requirements but also demonstrating their commitment to responsible manufacturing practices and environmental stewardship.

In conclusion, the global aluminum welding market is poised for continuous growth driven by technological advancements, industry trends, regional dynamics, and sustainability initiatives. As market players strive to meet the evolving needs of customers and adapt to changing market conditions, the emphasis on automation, lightweight materials, regional expansion, and sustainability will continue to shape the future of the aluminum welding industry. By leveraging innovation, strategic partnerships, and customer-centric approaches, companies can navigate the competitive landscape and capitalize on emerging opportunities in the market.

Discover the company’s competitive share in the industry

https://www.databridgemarketresearch.com/reports/global-aluminum-welding-market/companies

Market Intelligence Question Sets for Aluminum Welding Industry

- How big is the current global Aluminum Welding Market?

- What is the forecasted Aluminum Welding Market expansion through 2032?

- What core segments are covered in the report on the Aluminum Welding Market?

- Who are the strategic players in the Aluminum Welding Market?

- What countries are part of the regional analysis in the Aluminum Welding Market?

- Who are the prominent vendors in the global Aluminum Welding Market?

Browse More Reports:

Global Lipase Inhibitors Obesity Drugs Market

Global Livestock Dewormer Market

Global Load Break Switch Market

Global Location Based Mapping Market

Global Low-Cost Satellite Market

Global Low Emission Market

Global Low Global Warming Potential (GWP) Refrigerants Market

Global Low Horse Power AC Motor Market

Global Long term evolution (LTE) advanced pro Market

Global Lymphadenopathy Market

Global Macroencapsulation Market

Global Magnesium Nitrate Hexahydrate Market

Global Manned Guarding Market

Global Marfan Syndrome Treatment Market

Global Marine Steering System Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com

"