How Polymers Are Transforming the Electric Vehicle Industry

Introduction

The rapid expansion of electric vehicles is transforming the automotive industry’s approach to materials, manufacturing, and vehicle architecture. The Electric Vehicle Car Polymer Market has gained strong momentum as polymers increasingly replace conventional materials in a wide range of vehicle components. From interior trims and exterior body panels to battery housings, wiring insulation, and structural parts, polymers are now essential to modern EV design. Their benefits include lightweight properties, corrosion resistance, high design flexibility, and efficiency in large-scale production. In electric vehicles, where reducing weight directly improves energy efficiency and driving range, polymers play a particularly critical role. As automakers focus on enhancing performance, safety, and sustainability while controlling costs, the demand for advanced polymer materials continues to rise, making this market a key part of the evolving electric mobility ecosystem.

Market Drivers

One of the strongest drivers of the Electric Vehicle Car Polymer Market is the industry-wide emphasis on lightweighting. Lower vehicle weight leads to improved battery efficiency and longer driving range, making lightweight polymers and polymer composites highly attractive alternatives to traditional metals. Automakers are increasingly using engineering plastics for both structural and non-structural components to balance performance, safety, and cost. Another important driver is the rapid growth of electric vehicle production worldwide, supported by government incentives, stricter emission regulations, and rising consumer demand for cleaner transportation solutions. As EV manufacturing volumes rise, the need for polymer-based components in interiors, exteriors, battery systems, and electrical architectures also increases. In addition, continuous progress in polymer science, including high-strength, heat-resistant, and flame-retardant materials, is expanding the scope of applications for polymers in electric vehicles, further supporting market growth.

Market Challenges

Despite its positive growth outlook, the Electric Vehicle Car Polymer Market faces several challenges. One key challenge is ensuring that polymer materials meet the strict safety, durability, and performance requirements of electric vehicles, particularly in critical areas such as battery enclosures, power electronics, and thermal management systems. These components must withstand high temperatures, mechanical stress, and long service life, which increases development and testing costs. Another challenge is raw material price volatility, especially for petrochemical-based polymers, which can affect production costs and supply chain stability. Sustainability and recycling are also important concerns, as regulators and consumers increasingly expect lower environmental impact and better end-of-life management of automotive materials. Moreover, competition from alternative lightweight materials such as aluminum, magnesium, and advanced composites means polymer suppliers must continuously innovate to maintain a strong competitive position.

Market Opportunities

The Electric Vehicle Car Polymer Market presents significant opportunities as the automotive sector accelerates its shift toward electrification. One major opportunity lies in the development of advanced polymers specifically designed for EV applications, including high-temperature-resistant materials for battery packs, lightweight structural polymers, and high-performance insulation materials for high-voltage systems. The growing focus on battery safety and thermal management is creating strong demand for polymers with enhanced flame-retardant and thermal stability properties. Another opportunity is the increasing emphasis on sustainable materials, which is driving interest in recyclable and bio-based polymer solutions. Emerging markets, where electric vehicle adoption is rising quickly, also offer attractive growth prospects. In addition, closer collaboration between automakers, battery manufacturers, and material suppliers can accelerate innovation and lead to long-term strategic partnerships.

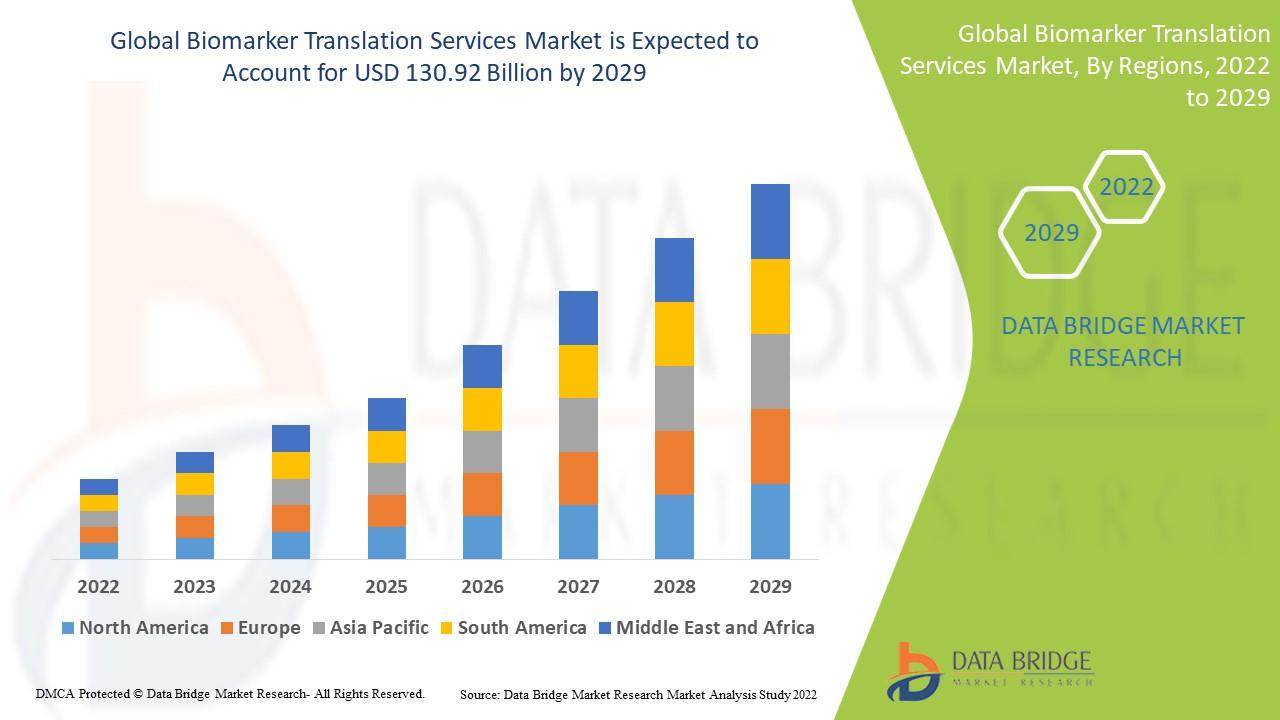

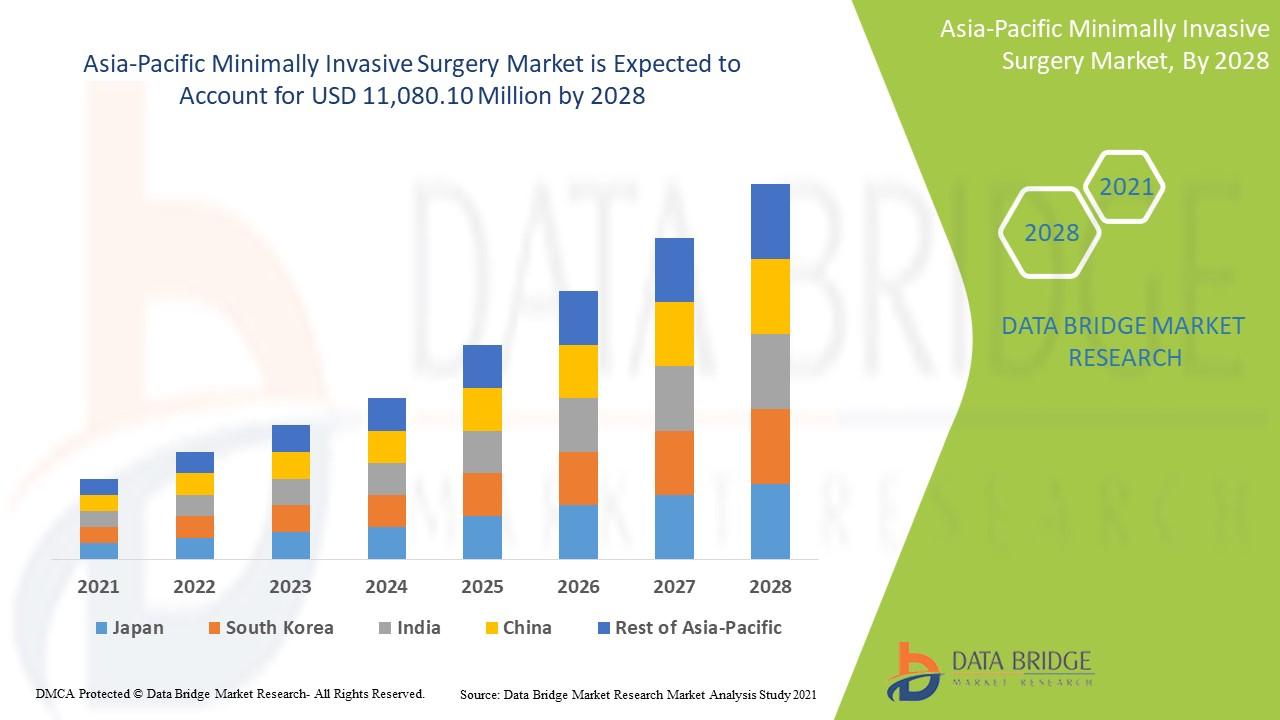

Regional Insights

Regional dynamics strongly influence the Electric Vehicle Car Polymer Market. Asia-Pacific remains a leading region, driven by high EV production volumes, strong government support for electric mobility, and a well-developed automotive and battery manufacturing ecosystem. Europe is another major market, supported by strict emission regulations, ambitious climate targets, and significant investment in electric vehicle and battery production. In this region, demand for advanced and sustainable polymer materials is particularly strong. North America also plays an important role, with growing EV adoption, technological innovation, and increasing investment in domestic EV manufacturing. Meanwhile, other regions such as Latin America and the Middle East and Africa are gradually emerging as growth markets as EV infrastructure improves and awareness of clean mobility solutions increases.

Future Outlook

The future of the Electric Vehicle Car Polymer Market is expected to be closely linked to the continued expansion of the global electric vehicle industry. As EV designs become more advanced, polymers are likely to be used in an even wider range of components to improve efficiency, safety, and overall vehicle performance. Ongoing research and development in high-performance, lightweight, and sustainable polymers will further broaden their application range in electric vehicles. The market is also expected to benefit from advances in manufacturing technologies, such as improved molding processes and additive manufacturing, which can enhance design flexibility and reduce production costs. At the same time, regulatory pressure and consumer expectations around sustainability will encourage wider adoption of recyclable and bio-based polymer solutions. Overall, the market is likely to experience steady growth driven by innovation, increasing EV production, and the ongoing push toward lightweight and energy-efficient vehicle designs.