From Prototyping to Production: 3D Printing Materials Market Gains Momentum

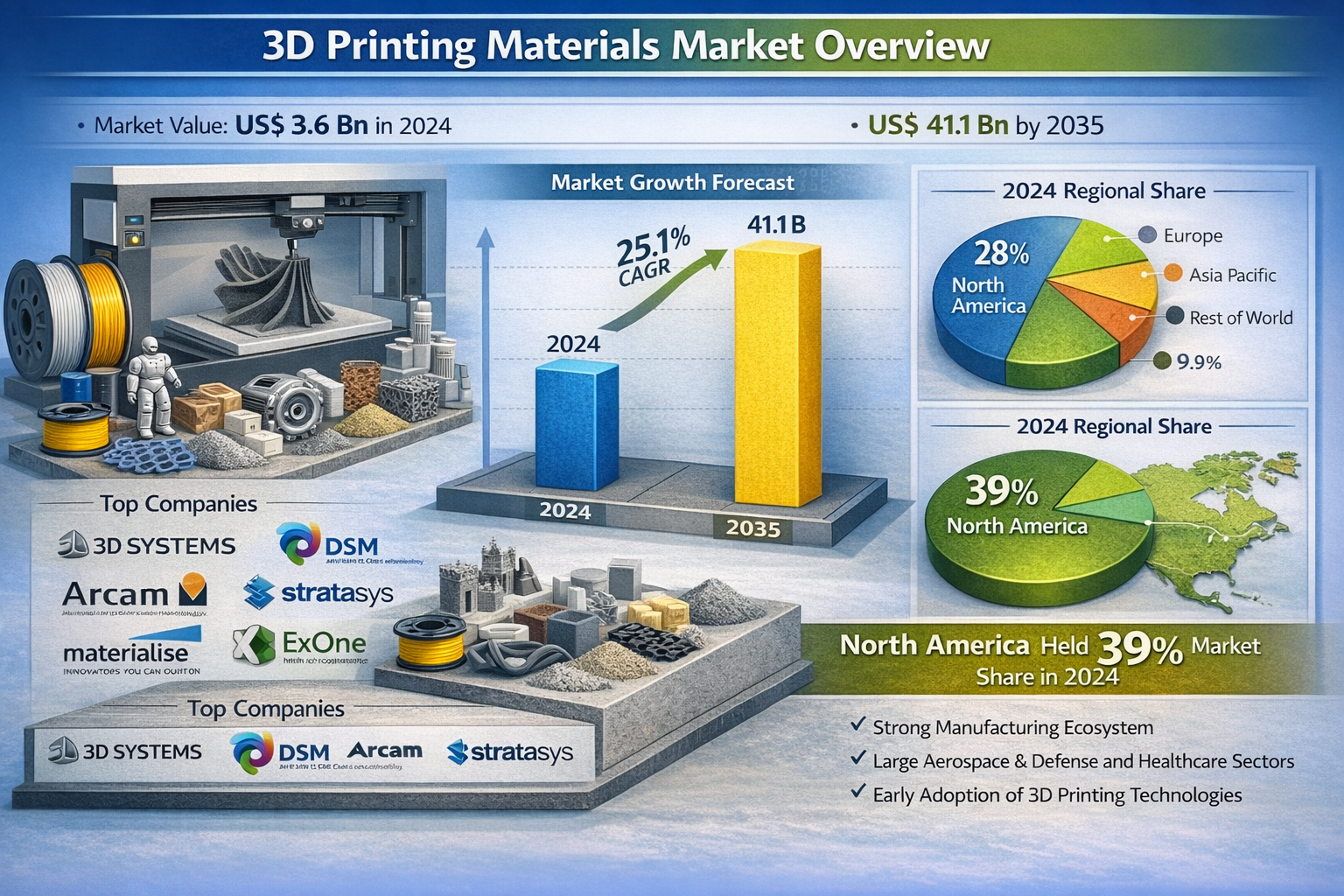

The global 3D printing materials market was valued at US$ 3.6 billion in 2024 and is projected to reach US$ 41.1 billion by 2035, expanding at a strong CAGR of 25.1% from 2025 to 2035. This rapid growth is driven by the increasing adoption of additive manufacturing across aerospace, defense, healthcare, and automotive industries, supported by continuous advancements in material innovation and a well-established manufacturing ecosystem, particularly in North America.

The 3D printing materials market is witnessing robust growth due to additive manufacturing being adopted at a wide scale across the verticals inclusive of healthcare, automotive, consumer products, and aerospace. The factors driving the growth are inclusive of rising demand for custom and lightweight components, advancements in material science, and increase in industrial automation.

Dive Deeper into Data: Get Your In-Depth Sample Now! https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=3605

The major players continue developing their material portfolios through investment in research and development pertaining to high-performance and sustainable 3D printing materials and partnerships with the other companies to expand their distribution channels.

Market Segmentation

|

Category |

Key Segments |

|

By Material Type |

Polymers (Plastics/Resins), Metals (Titanium, Stainless Steel, Aluminum), Ceramics, Composites (Carbon Fiber), Bio-inks |

|

By Form |

Filament, Powder, Liquid/Resin |

|

By Sourcing Type |

In-house production, Outsourced Service Bureaus |

|

By Application |

Prototyping, Functional Parts, Tooling & Fixtures, Medical Implants |

|

By Industry Vertical |

Aerospace & Defense, Automotive, Healthcare, Consumer Goods, Construction, Education |

Regional Analysis

- North America: Holds the largest market share (approx. 38%–41%). This dominance is driven by heavy investment in the US aerospace and defense sectors, as well as a robust ecosystem of tech giants like 3D Systems and Stratasys.

- Asia-Pacific: The fastest-growing region. China, India, and Japan are transforming into additive manufacturing hubs, leveraging 3D printing to reduce supply chain dependencies and fuel massive consumer electronics and automotive sectors.

- Europe: A leader in material innovation and sustainability, with Germany acting as a key hub for metal additive manufacturing and high-end industrial engineering.

Market Drivers and Challenges

Drivers

- Demand for Lightweighting: Aerospace and automotive sectors are using 3D-printed composites and titanium to reduce weight, directly improving fuel efficiency.

- Personalized Healthcare: The ability to print patient-specific implants, prosthetics, and dental crowns using biocompatible materials.

- Supply Chain Resilience: 3D printing allows for "on-demand" spare parts, reducing the need for massive physical inventories and mitigating global shipping disruptions.

Challenges

- High Raw Material Costs: High-purity metal powders and specialty filaments remain significantly more expensive than materials used in traditional injection molding or CNC machining.

- Standardization Gap: A lack of universal testing methods for the mechanical properties of printed parts can hinder large-scale adoption in safety-critical industries.

- Post-Processing Needs: Many materials require extensive cleaning, curing, or heat treatment after printing, adding time and cost.

Market Trends & Future Outlook

- Sustainable & Bio-based Materials: There is a surge in demand for recycled polymers and biodegradable filaments to align with global net-zero goals.

- Multi-Material Printing: The next decade will see the maturation of systems that can print multiple materials (e.g., a rigid plastic with an integrated conductive metal circuit) in a single build.

- Hybrid Manufacturing: A growing trend of combining additive manufacturing for complex shapes with subtractive CNC machining for precision finishing.

- Decentralized Production: Moving from "Mass Production" to "Mass Customization," where local micro-factories print goods near the end consumer.

Elevate Your Business Strategy! Purchase the Report for Market-Driven Insights: https://www.transparencymarketresearch.com/checkout.php?rep_id=3605<ype=S

Competitive Landscape

The market is highly competitive, featuring a mix of established chemical giants and specialized 3D printing firms.

- Key Players: Stratasys Ltd., 3D Systems, EOS GmbH, Arkema S.A., Materialise NV, BASF (Forward AM), Höganäs AB, and HP Development Company.

- Strategy: Companies are increasingly focusing on vertical integration—developing proprietary materials optimized specifically for their own hardware to ensure quality and recurring revenue.

Recent Developments (2025)

- HP Additive Manufacturing recently unveiled new closed-loop powder handling systems to minimize waste and labor.

- Aerospace-grade Titanium: New certifications for 3D-printed flight-critical parts have shifted the technology from experimental to serial production in 2025.

- Sustainability Partnerships: Major material providers like Arkema and Covestro are launching bio-attributed high-performance polymers to reduce the carbon footprint of industrial parts.

Key Study Point: By 2035, revenue from material demand is expected to outpace revenue from hardware sales, as the installed base of printers requires a continuous supply of high-value feedstocks.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com