Industrial embossing presses Innovations Driving High-Volume Metal Forming

The metal embossing machine market has seen significant growth over the past decade, driven by increased demand for decorative metal products, industrial applications, and advanced manufacturing techniques. Metal embossing machines are designed to create raised or recessed patterns on metal sheets, which find extensive use in automotive, construction, aerospace, and packaging industries. The market has witnessed innovations in automation, precision control, and digital integration, enabling manufacturers to produce intricate designs with higher efficiency and minimal material wastage. Metal embossing not only enhances the aesthetic appeal of metal sheets but also increases their structural rigidity, making them suitable for diverse applications.

Industrial Embossing Presses are specialized machines designed to create embossed patterns and designs on metal surfaces. The demand for industrial embossing presses is rising as manufacturers seek to enhance the aesthetic appeal and functionality of metal products. These presses are widely used in various industries, including automotive, consumer goods, and construction. As the trend towards customized and decorative metal products continues, the market for industrial embossing presses is anticipated to expand significantly, driven by the need for high-quality embossing solutions.

As industries continue to adopt lightweight and durable materials, the demand for precision embossing solutions has surged. The emergence of computer-controlled embossing machines has transformed the market, allowing businesses to produce customized designs with higher speed and consistency. Manufacturers are investing in research and development to introduce energy-efficient machines that reduce operational costs and improve environmental sustainability. The market is characterized by both global players and regional manufacturers, each offering a wide range of products to cater to small, medium, and large-scale industrial needs.

Market Drivers and Opportunities

Several factors are driving the growth of the metal embossing machine market. One of the primary drivers is the rising demand for aesthetically enhanced products across automotive interiors, household appliances, and decorative panels. Additionally, the increasing adoption of metal embossing in packaging solutions, particularly for premium products, is contributing to market expansion. Technological advancements, such as laser-assisted embossing and hydraulic embossing systems, are providing manufacturers with greater precision, faster processing times, and higher repeatability.

The market also offers opportunities in emerging economies where industrialization and urbanization are accelerating infrastructure development. Local manufacturers are increasingly opting for advanced metal embossing machines to enhance production capabilities while maintaining cost efficiency. Moreover, customization trends in automotive and consumer electronics sectors present additional growth potential, as embossing machines allow brands to offer unique designs to their customers.

Challenges and Restraints

Despite the growth potential, the metal embossing machine market faces certain challenges. High initial investment costs for advanced embossing machines can be a barrier for small and medium-sized enterprises. Additionally, the need for skilled operators to handle complex machinery and ensure precision can limit adoption. Fluctuations in raw material prices and global supply chain disruptions may also impact market stability. Manufacturers must balance cost, efficiency, and technological sophistication to remain competitive.

Environmental regulations regarding energy consumption and waste management also influence market dynamics. Companies are increasingly adopting eco-friendly embossing solutions to reduce carbon footprints while adhering to global sustainability standards. Developing energy-efficient and low-maintenance embossing machines remains a key focus for industry players.

Regional Insights

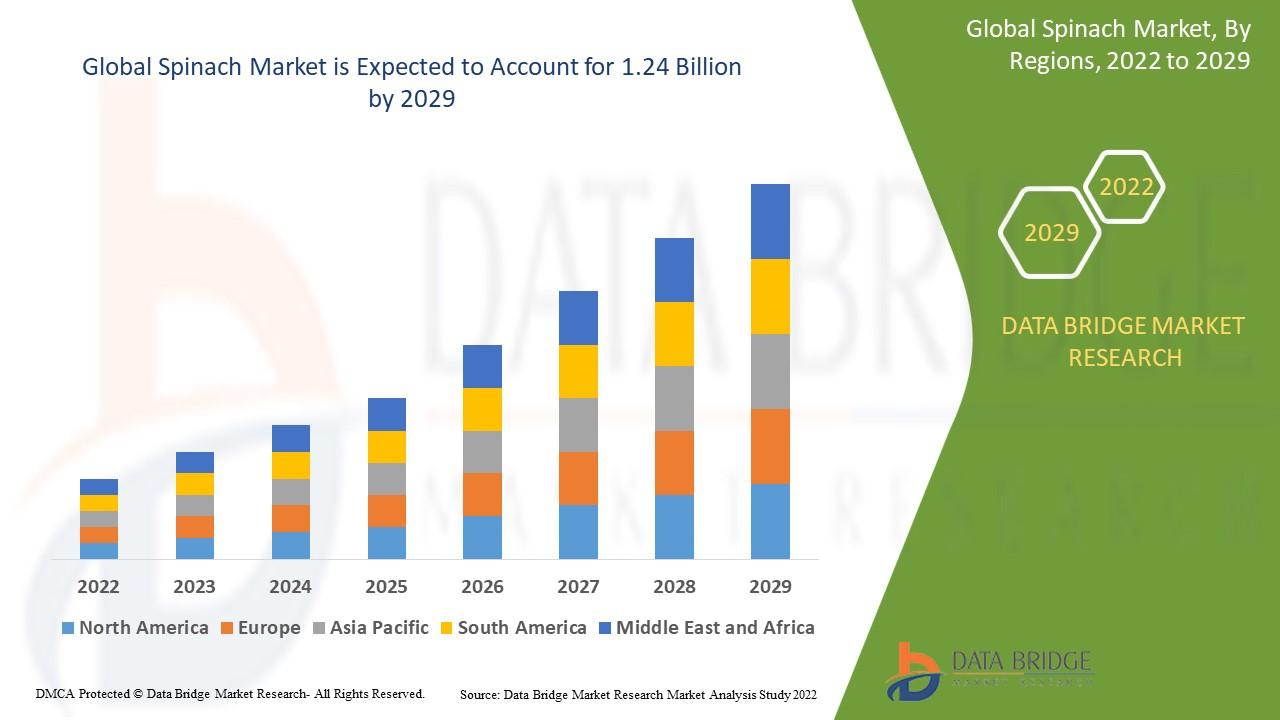

The metal embossing machine market is witnessing varied growth across regions. North America and Europe are mature markets, driven by automotive, aerospace, and packaging industries. Asia-Pacific, particularly China and India, is experiencing rapid growth due to increasing industrialization, infrastructure projects, and rising disposable incomes. The Middle East and Latin America are emerging markets where government initiatives to boost manufacturing and construction are supporting demand for metal embossing machines.

Future Trends

Looking ahead, the metal embossing machine market is likely to experience continued innovation through digitalization and automation. Smart machines integrated with IoT sensors and AI-driven design software will enable predictive maintenance, real-time monitoring, and greater efficiency. The focus on lightweight and high-strength metals in industries such as aerospace and automotive will further fuel demand. Manufacturers are expected to invest in environmentally friendly technologies and energy-efficient machinery to align with global sustainability trends.

FAQs

Q1: What industries use metal embossing machines?

Metal embossing machines are widely used in automotive, aerospace, construction, packaging, and decorative industries for both functional and aesthetic purposes.

Q2: Are automated metal embossing machines cost-effective?

Yes, automated machines may require higher initial investment but reduce labor costs, improve precision, and increase production efficiency over time.

Q3: What is the key trend in the metal embossing machine market?

The major trend is the adoption of digital and AI-integrated machines that offer customization, predictive maintenance, and energy efficiency.