How V-Shaped Compressors Improve Industrial Efficiency

Introduction

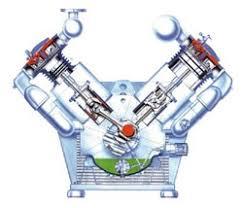

The V Shaped Compressors Market is experiencing steady growth as industries worldwide adopt compact, efficient, and high-performance air compression systems for manufacturing, automotive, construction, and industrial applications. V-shaped compressors, designed with cylinders arranged in a “V” configuration, offer superior balance, reduced vibration, and high volumetric efficiency. Their ability to deliver consistent airflow, operate reliably under heavy loads, and maintain better cooling performance makes them preferred in workshops, production plants, pneumatic tool operations, and maintenance facilities. With rising industrial automation, expanding manufacturing output, and increasing demand for energy-efficient compressed air systems, V-shaped compressors are becoming a critical component of modern industrial infrastructure.

Market Drivers

Growing demand for pneumatically powered tools in automotive workshops, metal fabrication units, and industrial assembly lines is a major driver for the market. Expanding construction activities and increasing use of portable compressors on job sites further strengthen adoption. V-shaped compressors offer improved durability and performance compared to conventional single-cylinder models, attracting industries seeking higher operational efficiency. Rising emphasis on energy efficiency and reduced maintenance costs supports the transition to advanced compressor technologies. Additionally, growth in small and medium-sized manufacturing units worldwide contributes significantly to market expansion.

Market Challenges

High initial cost of premium V-shaped compressors may limit adoption among small-scale businesses. Operational noise and heat generation can be concerns in enclosed environments without proper ventilation. Regular maintenance is required to ensure consistent performance, including lubrication, filter changes, and cylinder inspections. Competition from rotary screw compressors and oil-free models may affect market share in specific applications. Supply chain fluctuations involving metal components and motors also pose challenges for manufacturers.

Market Opportunities

Significant opportunities lie in developing energy-efficient, low-noise V-shaped compressors with improved cooling systems. Integration of smart sensors and IoT-based monitoring enables predictive maintenance and enhances uptime. Demand for portable and lightweight compressor models is increasing in construction, automotive service, and DIY applications. Emerging economies with expanding industrial bases offer major growth opportunities for compressor manufacturers. Sustainable and oil-free variants also present new market potential for industries with strict contamination standards.

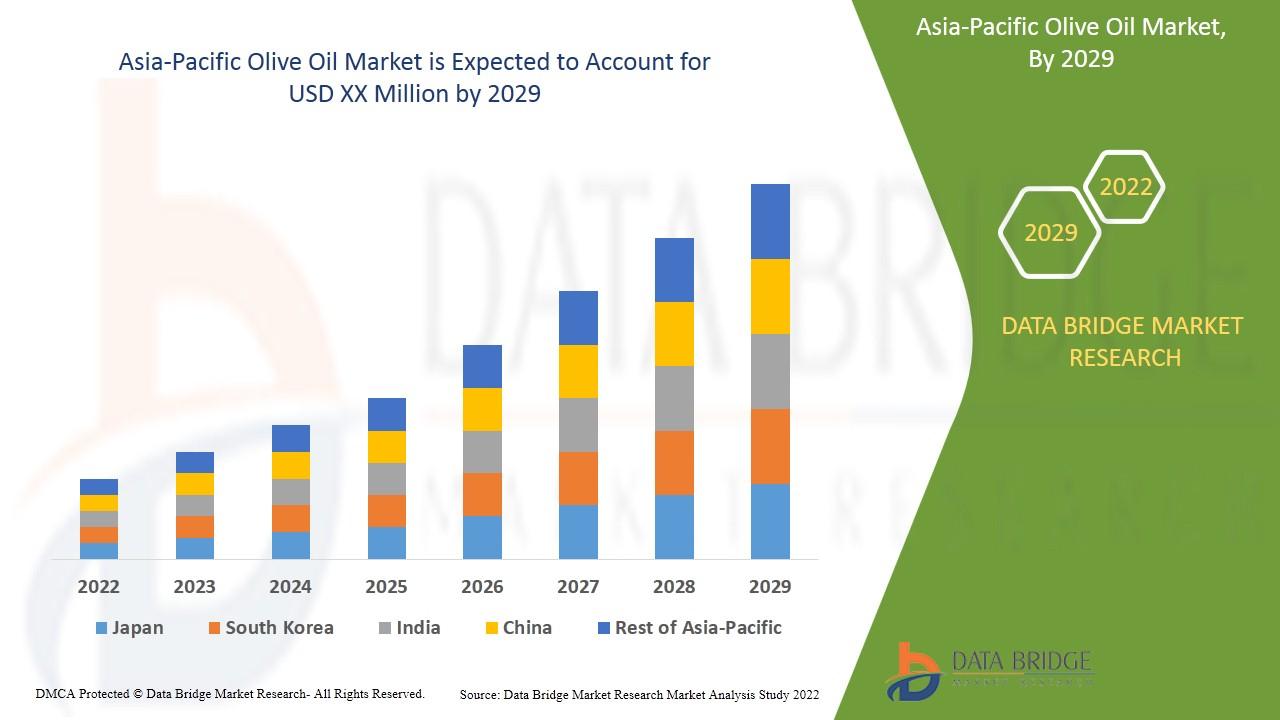

Regional Insights

Asia-Pacific dominates the V Shaped Compressors Market due to rapid industrialization, growth in automotive repair services, and expanding factory infrastructure in China, India, and Southeast Asia. North America shows steady adoption driven by manufacturing modernization and demand for high-quality workshop equipment. Europe maintains strong market presence supported by engineering excellence, automation trends, and stringent efficiency standards. The Middle East and Latin America reflect growing adoption as construction and industrial activities increase. Africa shows emerging demand as small industries and infrastructure projects expand.

Future Outlook

The future of the V Shaped Compressors Market will be influenced by energy-efficient design improvements, digital connectivity, and broader industrial automation. Smart compressors equipped with real-time monitoring, automatic load adjustment, and predictive diagnostics will become standard features. Hybrid and oil-free technologies will gain traction in industries requiring clean compressed air. As global manufacturing output increases, demand for compact, durable, and high-performance compressors will continue rising. Overall, the market is positioned for sustained growth supported by innovation, expanding industrial activities, and evolving application needs.

Conclusion

V-shaped compressors are becoming essential in workshops, industrial plants, and construction sites due to their durability, efficiency, and balanced operation. Despite challenges involving cost, maintenance, and competition from alternative compressor technologies, the market remains strong. Innovations in cooling systems, smart monitoring, and noise reduction will shape the next generation of compressors. As automation and industrial expansion continue globally, V-shaped compressors will remain a vital part of the compressed air ecosystem.