Pharmaceutical Isolator Market Innovation, Size, Share, Growth and Trend Analysis By 2032

Executive Summary Pharmaceutical Isolator Market Size and Share: Global Industry Snapshot

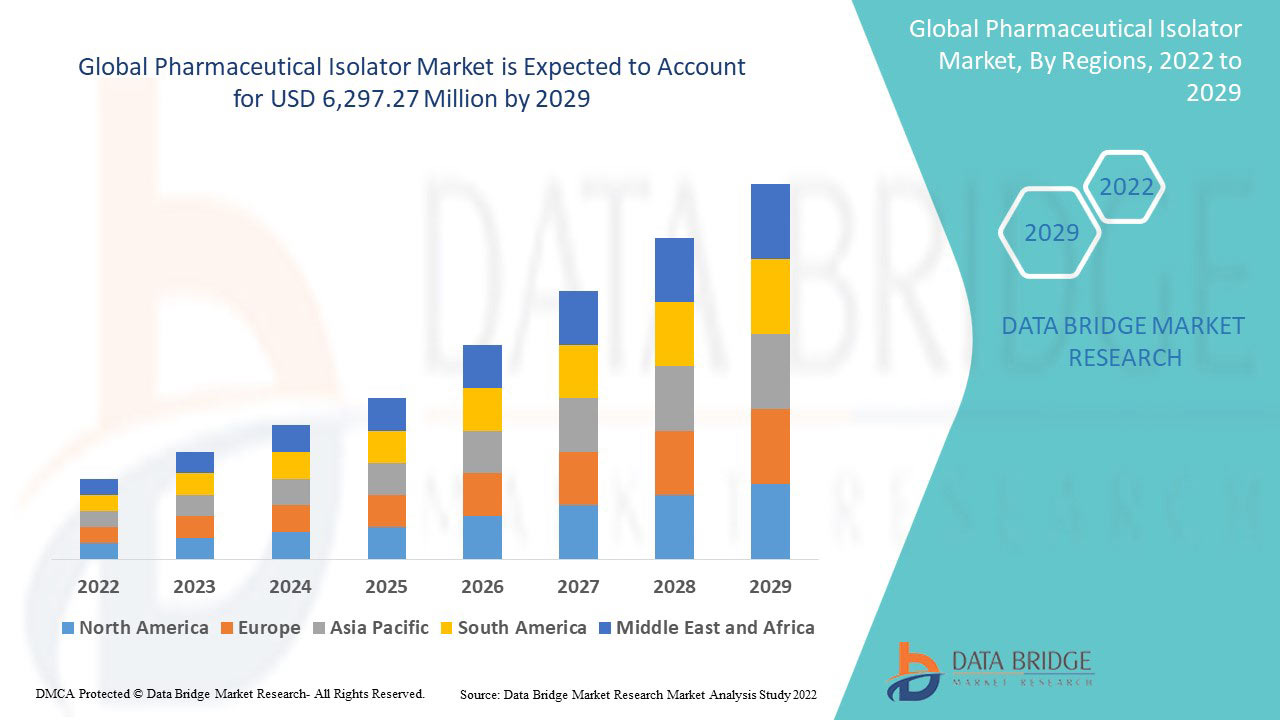

Data Bridge Market Research analyzes that the global pharmaceutical isolator market is expected to reach the value of USD 6,297.27 million by 2029, at a CAGR of 14.3% during the forecast period.

Pharmaceutical Isolator Market report offers the most appropriate solution for the business requirements in many ways. To be successful in this competitive age, it is very imperative to get well-versed about the major happenings in the Pharmaceutical Isolator Market industry which is possible only with the excellent market report like this one. To make aware about the industry insights so that business never misses anything, this is the valuable market report. The report also analyzes the market status, market share, growth rate, sales volume, future trends, market drivers, market restraints, revenue generation, opportunities and challenges, risks and entry barriers, sales channels, and distributors. A large scale Pharmaceutical Isolator Market report not only assists with the informed decision making but also helps with smart working.

The top notch Pharmaceutical Isolator Market report defines various segments related to Pharmaceutical Isolator Market industry and market with thorough research and analysis. These can be listed as; industry outlook, critical success factors (CSFs), industry dynamics, market drivers, market restraints, market segmentation, value chain analysis, key opportunities, application and technology outlook, regional or geographical insight, country-level analysis, key company profiles, competitive landscape, and company market share analysis. So, business can surely go with an all-embracing Pharmaceutical Isolator Market research report to take business to the highest level of growth and success.

Stay informed with our latest Pharmaceutical Isolator Market research covering strategies, innovations, and forecasts. Download full report: https://www.databridgemarketresearch.com/reports/global-pharmaceutical-isolator-market

Pharmaceutical Isolator Market Trends & Analysis

Segments

- By Type: Aseptic Isolators, Containment Isolators, Bio Isolators, Sampling and weighing Isolators

- By System: Closed Systems, Open Systems

- By Pressure Differentials: Positive Pressure Units, Negative Pressure Units

The global pharmaceutical isolator market is segmented based on type, system, and pressure differentials. Aseptic isolators, containment isolators, bio isolators, and sampling and weighing isolators are the key types of isolators prevalent in the market. When it comes to systems, closed systems and open systems are the two main categories. Additionally, pressure differentials play a crucial role, with positive pressure units and negative pressure units being the main segments. These distinct segments each cater to specific needs within the pharmaceutical industry, ensuring that a wide range of requirements can be met efficiently and effectively.

Market Players

- COMECER S.p.A.

- Hosokawa Micron Ltd

- I.M.A. INDUSTRIA MACCHINE AUTOMATICHE S.P.A.

- Robert Bosch GmbH

- Skan AG

- Fedegari Autoclavi S.p.A.

- Watson-Marlow Fluid Technology Group

- Germfree

- MBRAUN

- TEPLA AG

- Extract Technology

In the global pharmaceutical isolator market, there are several key players who are making significant contributions to the industry. Companies such as COMECER S.p.A., Hosokawa Micron Ltd, I.M.A. INDUSTRIA MACCHINE AUTOMATICHE S.P.A., Robert Bosch GmbH, and Skan AG are some of the prominent players driving innovation and advancements in isolator technology. Others like Fedegari Autoclavi S.p.A., Watson-Marlow Fluid Technology Group, Germfree, MBRAUN, TEPLA AG, and Extract Technology also play vital roles in the market, offering a wide range of products and solutions to meet the diverse needs of pharmaceutical companies worldwide.

The global pharmaceutical isolator market is witnessing substantial growth due to various factors such as the increasing focus on sterility assurance in pharmaceutical production, the need to comply with stringent regulatory requirements, and the rising demand for advanced containment solutions to prevent cross-contamination. As pharmaceutical companies strive to maintain high standards of product quality and safety, the adoption of isolator systems continues to rise steadily. These systems provide a controlled environment that minimizes the risk of product contamination and ensures the protection of both operators and products during various manufacturing processes.

One of the key trends shaping the pharmaceutical isolator market is the growing preference for customized isolator solutions tailored to specific production requirements. Companies are increasingly seeking isolator systems that can be seamlessly integrated into their existing production lines, offering flexibility and scalability to accommodate changing operational needs. Customized isolators also enable pharmaceutical manufacturers to enhance operational efficiency, reduce production downtime, and optimize workflow processes, ultimately leading to cost savings and improved overall productivity.

Another significant trend in the pharmaceutical isolator market is the integration of advanced technologies such as robotics and automation to enhance isolator performance and operational capabilities. Automated isolator systems equipped with robotic arms and intelligent control systems enable precise handling of materials, reduce human intervention, and minimize the risk of errors or accidents during pharmaceutical manufacturing processes. By leveraging automation, companies can streamline production operations, improve process consistency, and achieve higher levels of product quality and safety.

Furthermore, the increasing emphasis on regulatory compliance and quality standards in the pharmaceutical industry is driving the adoption of advanced isolator systems that meet or exceed global regulatory guidelines. Pharmaceutical companies are investing in isolator technologies that offer superior containment levels, reliable aseptic processing, and strict environmental control to ensure compliance with regulatory requirements such as Good Manufacturing Practices (GMP) and international pharmacopeial standards. The integration of cutting-edge features such as isolator monitoring systems, HEPA filtration units, and continuous monitoring of critical parameters further enhances the safety and reliability of pharmaceutical manufacturing processes.

In conclusion, the global pharmaceutical isolator market is poised for significant growth and innovation driven by evolving industry dynamics, technological advancements, and changing regulatory landscape. As pharmaceutical manufacturers continue to prioritize product quality, operational efficiency, and regulatory compliance, the demand for high-performance isolator solutions is expected to surge in the coming years. By leveraging customized solutions, advanced technologies, and stringent quality standards, companies can enhance their manufacturing capabilities, mitigate risks, and drive sustainable growth in the competitive pharmaceutical market landscape.The global pharmaceutical isolator market is a dynamic and rapidly evolving sector driven by various factors such as the increasing emphasis on sterility assurance, stringent regulatory requirements, and the need for advanced containment solutions. One of the significant trends in the market is the rising demand for customized isolator solutions tailored to specific production needs. Companies are increasingly looking for isolator systems that can seamlessly integrate into their existing operations, offering flexibility, scalability, and improved operational efficiency. Customized isolators not only enhance productivity but also optimize workflow processes, leading to cost savings and better overall outcomes for pharmaceutical manufacturers.

Another key trend shaping the pharmaceutical isolator market is the integration of advanced technologies like robotics and automation. Automated isolator systems with robotic arms and intelligent controls enable precise handling of materials, reduce human intervention, and enhance operational capabilities. By embracing automation, companies can streamline production processes, ensure consistency, and elevate product quality and safety standards. The incorporation of cutting-edge features such as isolator monitoring systems and HEPA filtration units further contributes to the safety and reliability of pharmaceutical manufacturing processes.

Moreover, regulatory compliance and adherence to quality standards continue to drive the adoption of advanced isolator systems in the pharmaceutical industry. Companies are investing in isolator technologies that offer superior containment levels, aseptic processing, and strict environmental control to meet global regulatory guidelines such as Good Manufacturing Practices (GMP) and pharmacopeial standards. By focusing on compliance and quality, pharmaceutical manufacturers can ensure the safety of products and processes, build trust among consumers, and enhance industry reputation.

Overall, the global pharmaceutical isolator market is poised for substantial growth and innovation in the coming years. With a relentless focus on quality, efficiency, and compliance, the demand for high-performance isolator solutions is projected to increase significantly. Companies that leverage customized solutions, advanced technologies, and best practices in the industry will position themselves for success in a competitive marketplace where operational excellence and product safety are paramount.

Learn about the company’s position within the industry

https://www.databridgemarketresearch.com/reports/global-pharmaceutical-isolator-market/companies

Pharmaceutical Isolator Market Overview: Strategic Questions for Analysis

- What does the current research say about the size of the Pharmaceutical Isolator Market?

- What is the predicted CAGR until the end of the forecast period?

- What are the significant components of the Pharmaceutical Isolator Market segmentation?

- Which market players hold a competitive edge?

- What innovations have taken place recently in the Pharmaceutical Isolator Market?

- What countries form the scope of the geographical study?

- Which region holds the title of fastest-growing?

- Which country is expected to hold a leadership position?

- Where is the majority of Pharmaceutical Isolator Market value concentrated?

- Which country’s growth outpaces others?

Browse More Reports:

Global Tapioca Modified Starch Market

Global Textile Home Decor Market

Global Toluene Market

Global Tryptophan Market

Global Urinalysis Market

Global Vehicle Lightweighting Market

Global Vertical Lift Module Market

Global Veterinary Analgesics/Anti-Inflammatory (NSAIDS) Market

Global Viscosupplementation Market

Global Volleyball Knee Pad Market

Global Webcams Market

Global Weighing and Inspection Market

Global Wireless Display Market

Asia-Pacific Adhesive Tapes Market

Europe Adhesive Tapes Market

North America Hydrocolloids Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com