The Rise of Intelligent and Torque-Vectoring Differentials

Introduction

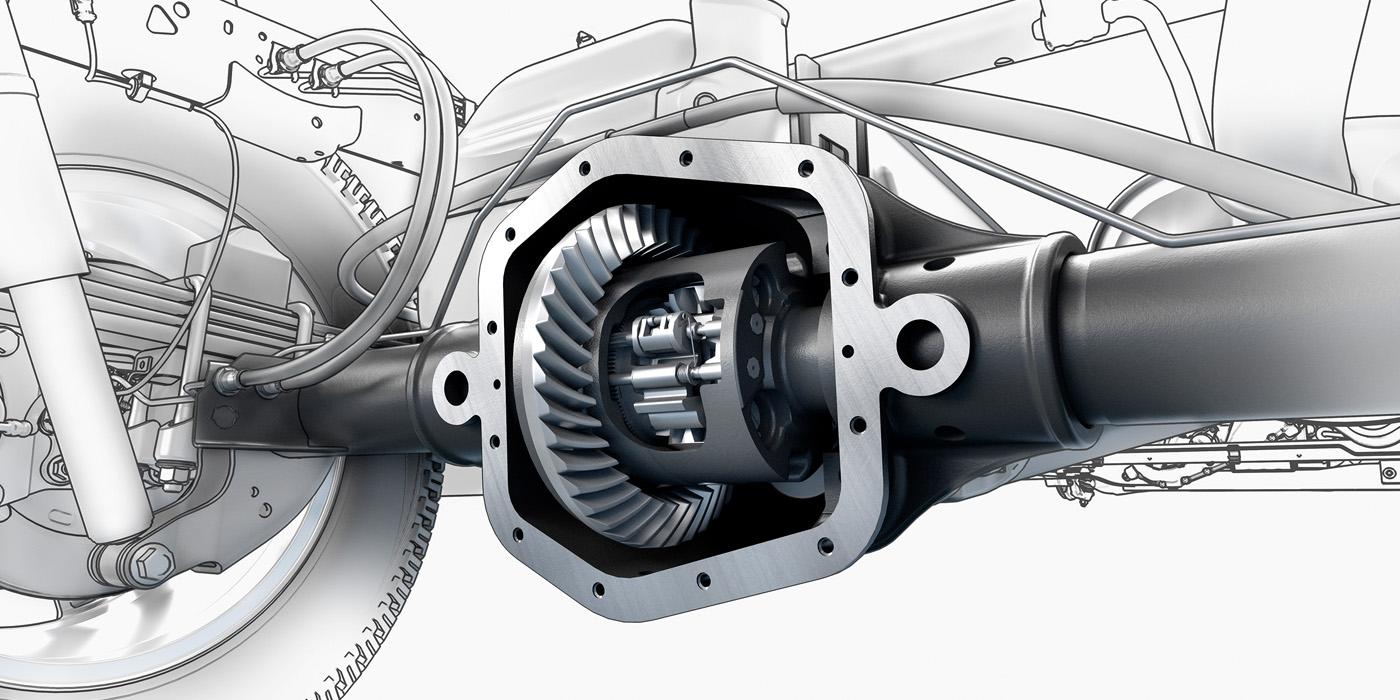

The Automotive Differential System Market is growing steadily as modern vehicles increasingly require advanced drivetrain technologies to enhance traction, stability, and driving performance. A differential system distributes engine torque to the wheels while allowing them to rotate at different speeds—critical for smooth cornering, improved control, and reduced tire wear. With rising production of passenger cars, SUVs, performance vehicles, and commercial fleets, the need for reliable and efficient differential systems has increased significantly. Technological advancements such as electronic limited-slip differentials (eLSD), torque-vectoring systems, and advanced 4WD/AWD configurations are enhancing vehicle safety, handling, and fuel efficiency. The market is projected to grow at a CAGR of around 5–6% over the forecast period, supported by increasing demand for off-road vehicles, electrification of drivetrains, and growth in the premium and sports vehicle segments. As automotive engineering evolves toward intelligent drivetrains and electrified mobility, differential systems are becoming more sophisticated and integral to vehicle dynamics.

Market Drivers

Rising consumer demand for SUVs, crossovers, AWD, and off-road-capable vehicles is a major driver for the automotive differential system market. Increasing focus on safety, stability, and improved handling has accelerated the adoption of advanced differential technologies such as limited-slip and torque-vectoring systems. Electrification trends are also influencing differential design, as electric and hybrid vehicles require specialized systems for efficient power distribution across axles or dual motors. Growth in premium and performance vehicles, where superior handling and traction are key value propositions, supports market expansion. Rapid urbanization, improving road networks, and rising disposable incomes in developing markets contribute to increased vehicle ownership and differential system demand. Additionally, continuous innovation in materials, lightweighting, and electronic control systems further strengthens market growth.

Market Challenges

High costs associated with advanced differential systems, especially electronic and torque-vectoring variants, limit adoption in budget and entry-level vehicles. Integration complexity of modern differentials with vehicle stability, braking, and traction control systems increases engineering time and manufacturing expenses. Wear and tear due to constant mechanical stress can lead to expensive maintenance or replacement, particularly in off-road and commercial vehicles. Supply chain disruptions affecting essential components, such as gears, bearings, and electronic control units, can hinder production. Long-term electrification poses challenges for traditional mechanical differentials, as fully electric vehicles with individual wheel motors may reduce the need for conventional differential units. Additionally, cost-sensitive markets often prioritize affordability over advanced driving performance features, slowing adoption.

Market Opportunities

Electrification and hybridization of vehicles present strong opportunities for intelligent differential systems engineered for e-AWD and multi-motor powertrains. Development of lightweight, high-strength, and low-friction differential components can improve fuel efficiency and reduce emissions, aligning with sustainability goals. Growing demand for electric SUVs, off-road EVs, and performance EVs will boost adoption of electronic and torque-vectoring differentials. Integration of AI, sensors, and advanced control algorithms will enable smart differentials capable of real-time torque distribution and predictive vehicle dynamics control. Aftermarket upgrades for high-performance differentials offer revenue potential among automotive enthusiasts and off-road users. Expanding production of commercial vehicles and logistics fleets in emerging markets provides opportunities for heavy-duty differential systems. Partnerships between OEMs, drivetrain suppliers, and technology firms will drive innovation in next-generation differential solutions.

Regional Insights

Asia-Pacific dominates the Automotive Differential System Market owing to large-scale vehicle production, strong presence of OEMs, rising SUV sales, and growing infrastructure development across China, India, Japan, and South Korea. China leads with rapid adoption of electric and hybrid vehicles requiring advanced drivetrains. North America shows strong demand driven by popularity of pickup trucks, SUVs, 4WD vehicles, and performance models in the U.S. and Canada. Europe maintains a significant share due to strict safety and emission regulations, advancements in drivetrain engineering, and a high concentration of premium automakers in Germany, France, and the UK. Latin America, the Middle East, and Africa are gradually adopting upgraded differential systems, supported by increasing vehicle sales, off-road usage, and commercial vehicle demand.

Future Outlook

The future of the Automotive Differential System Market will be shaped by electrification, intelligent control, and lightweighting trends. Torque-vectoring and electronic limited-slip differentials will become mainstream as vehicles adopt more advanced traction and stability systems. Fully electric vehicles will drive development of new differential architectures tailored to multi-motor and wheel-specific torque control designs. AI-enabled differentials capable of predictive handling adjustments will enhance vehicle safety and performance in autonomous and connected vehicles. Sustainability will influence manufacturing through recyclable materials, low-friction designs, and cleaner production methods. Modular differential platforms enabling flexible integration across multiple vehicle models will reduce costs and accelerate adoption. As mobility evolves toward smart and electrified drivetrains, differential systems will continue to play a central role in ensuring optimal traction, safety, and driving dynamics.

Conclusion

The Automotive Differential System Market is evolving as automakers enhance drivetrain performance, safety, and efficiency to meet changing mobility demands. Differential systems play a crucial role in delivering smooth handling, improved traction, and superior vehicle stability across driving conditions. While high costs and long-term electrification trends present challenges for traditional mechanical differentials, innovation in electronic, torque-vectoring, and e-AWD systems is unlocking new opportunities. With rising SUV and EV adoption, growing demand for premium driving experiences, and continuous advancements in drivetrain technology, the market is well positioned for sustained growth. As the automotive industry transitions toward connected, intelligent, and electrified mobility, differential systems will remain integral to next-generation vehicle performance.