The Transformative Power of Modern 3D Simulation Software

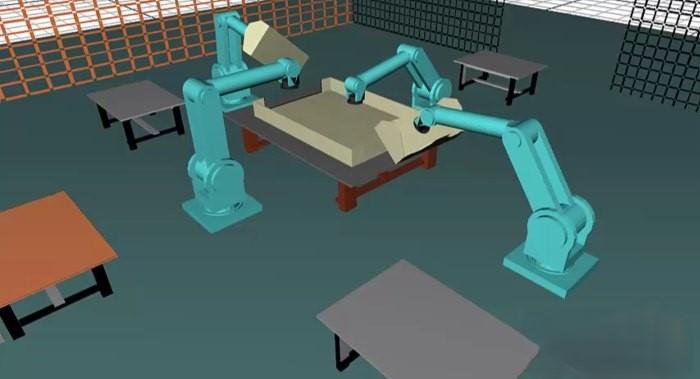

In the vanguard of industrial innovation, 3D Simulation Software has emerged as a cornerstone technology, enabling engineers, designers, and scientists to visualize, analyze, and optimize products and processes in a virtual environment before committing to physical production. This powerful software creates a digital replica of a system, allowing users to test its performance under a wide range of conditions, identify potential flaws, and iterate on designs with unprecedented speed and accuracy. The immense strategic value of this capability is driving a massive wave of adoption across numerous sectors, fueling a market that is poised for explosive growth. Industry projections indicate that the market size will surge to USD 33.87 Billion by 2034, expanding at an impressive compound annual growth rate (CAGR) of 17.20% between 2025 and 2034, signaling a fundamental shift toward digitally-driven product development.

The core function of 3D simulation is to bridge the gap between theoretical design and real-world performance. By applying the principles of physics through complex mathematical models, this software can accurately predict how a product will behave under stress, heat, fluid flow, or electromagnetic forces. For an automotive engineer, this means crash-testing a new car model hundreds of times digitally to perfect its safety features without ever building a physical prototype. For an aerospace company, it means simulating the aerodynamic properties of a new wing design to maximize fuel efficiency. This process of "virtual testing" dramatically reduces the reliance on expensive and time-consuming physical prototypes, accelerates the research and development (R&D) cycle, and empowers organizations to bring more innovative and reliable products to market faster than ever before, providing a clear and substantial return on investment.

The applications of this technology are incredibly diverse, touching nearly every aspect of modern manufacturing and engineering. In the field of electronics, it is used to simulate heat dissipation in microchips to prevent overheating. In the healthcare industry, it allows for the simulation of blood flow through a patient-specific artificial heart valve to optimize its design before surgery. Even in architecture and construction, it is used to simulate wind loads on a skyscraper or the acoustics of a concert hall. This versatility has made 3D simulation an indispensable tool for innovation. It democratizes the process of complex analysis, putting capabilities that were once the exclusive domain of supercomputers and specialized research labs into the hands of a much broader range of engineers and designers, thereby fueling a culture of continuous improvement and data-driven design.

Beyond simple product validation, 3D simulation is becoming a central component of the entire product lifecycle management (PLM) process. It is used in the conceptual design phase to explore new ideas, during the detailed engineering phase for optimization, and even in the manufacturing phase to simulate production processes like casting or stamping to improve yield and reduce defects. As we look forward, the integration of simulation with real-world data from IoT sensors is giving rise to the concept of the "digital twin"—a living virtual model that continuously mirrors a physical asset. This synergy between the virtual and physical worlds represents the next frontier of industrial efficiency and innovation, ensuring that 3D simulation software will remain a critical and rapidly growing technology for decades to come.

Explore Our Latest Trending Reports: