Aluminum Cable Solutions for Modern Power Networks : High-Performance Conductors from HNBF Power

Aluminum cable has become a core material for modern power transmission and distribution systems. From urban substations to rural overhead lines and industrial power networks, utilities and EPC contractors increasingly rely on aluminum conductors to balance electrical performance, mechanical reliability, and project cost efficiency.

As a global manufacturer of overhead conductors and power cables, HNBF Power provides a full portfolio of aluminum cable products engineered for demanding grid environments, including AAC, AAAC, ACSR, ABC, LV power cable, and concentric cable solutions. This guide explains what aluminum cable is, where it performs best, and how engineers and procurement teams can select the right solution for long-term network reliability.

What Is Aluminum Cable?

Aluminum cable refers to electrical conductors that use aluminum as the primary current-carrying material. Compared with copper, aluminum offers:

-

Lower material cost

-

Significantly lighter weight

-

Good electrical conductivity per unit mass

-

High corrosion resistance when properly designed

These advantages make aluminum cable the preferred option for overhead transmission and many distribution and industrial power applications.

For utilities and infrastructure developers, aluminum conductors allow longer spans, reduced structural loading on towers and poles, and optimized installation productivity.

Why Aluminum Cable Is Widely Used in Power Systems

Lightweight Structure for Long Spans

One of the main engineering advantages of aluminum cable is its low density. Lighter conductors reduce mechanical stress on towers, poles, insulators, and foundations. This is especially important for long-span overhead lines, river crossings, and mountainous transmission routes.

Competitive Electrical Performance

Although aluminum has lower conductivity than copper by volume, modern aluminum conductor designs compensate through optimized cross-section and stranded construction. For most medium- and high-voltage networks, aluminum cable provides excellent current-carrying capability and thermal performance.

Cost Efficiency for Large-Scale Projects

For grid expansion, renewable energy integration, and rural electrification, material cost has a direct impact on project feasibility. Aluminum cable delivers reliable performance at a lower total installed cost, making it ideal for utility and EPC projects with strict budget controls.

Main Types of Aluminum Cable Used in Power Networks

AAC – All Aluminum Conductor

AAC cable is composed entirely of stranded aluminum wires. It offers high conductivity and excellent corrosion resistance, making it suitable for short-span distribution lines, coastal environments, and urban overhead networks.

AAAC – All Aluminum Alloy Conductor

AAAC uses aluminum-magnesium-silicon alloy strands. Compared with AAC, it provides higher tensile strength and better sag characteristics, making it suitable for longer spans and higher mechanical loads.

ACSR – Aluminum Conductor Steel Reinforced

ACSR combines aluminum strands with a galvanized steel core. The steel reinforcement significantly improves tensile strength and allows very long spans, high wind loads, and heavy ice conditions. ACSR remains one of the most widely used aluminum cable solutions for high-voltage transmission lines worldwide.

ABC – Aerial Bundled Cable

ABC aluminum cable systems are insulated conductors bundled together for low- and medium-voltage overhead distribution. They improve public safety, reduce power theft, and perform well in congested urban areas and tree-dense corridors.

LV Aluminum Power Cable and Concentric Cable

For underground and industrial installations, aluminum LV power cables and concentric neutral cables provide cost-effective solutions for service connections, substations, commercial buildings, and utility distribution feeders.

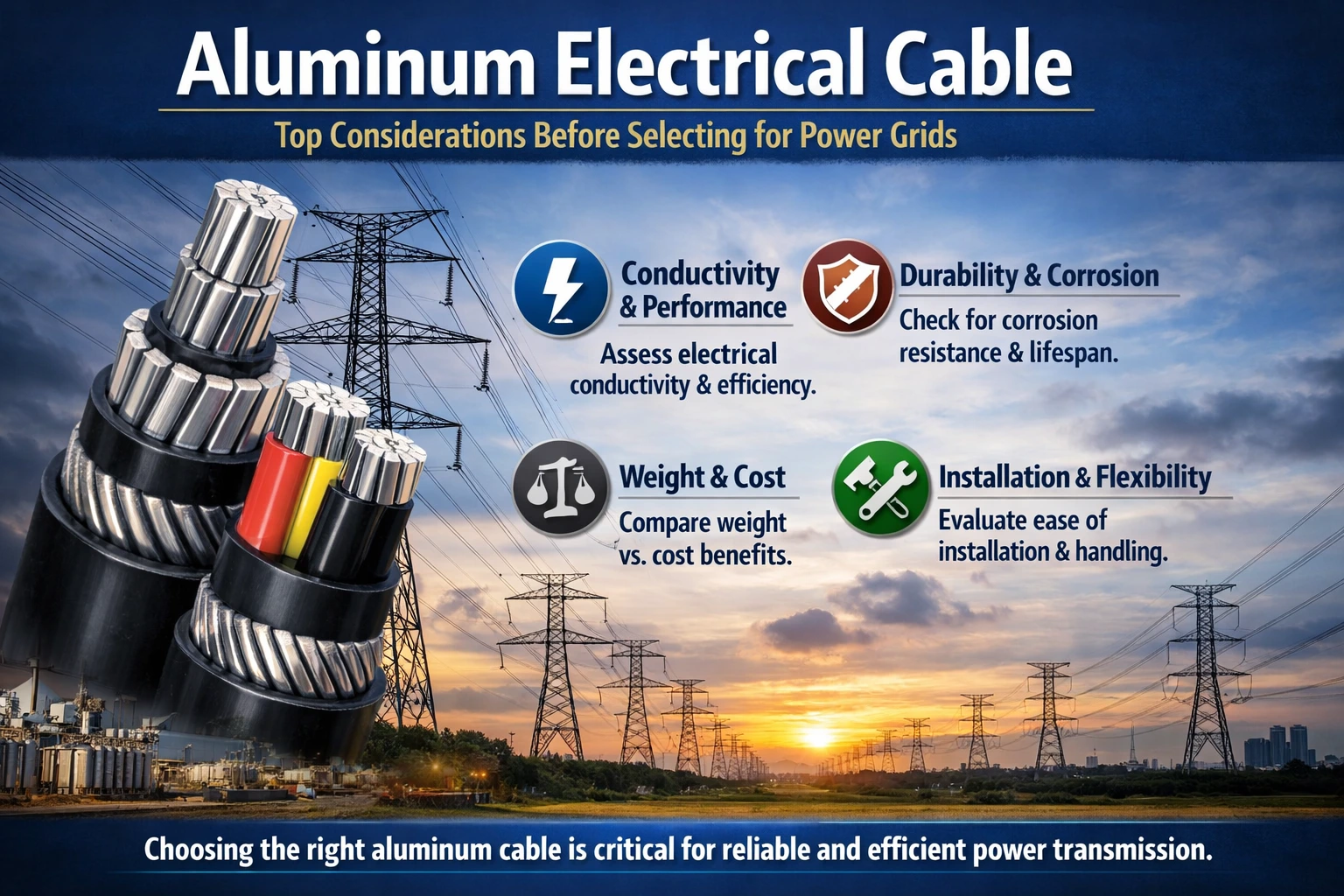

Key Engineering Factors When Selecting Aluminum Cable

Conductor Size and Current Rating

The selected aluminum cable cross-section must meet the required continuous current, emergency overload rating, and permissible conductor temperature. Thermal calculations should account for ambient conditions, solar radiation, and installation method.

Mechanical Strength and Sag Control

For overhead applications, conductor tension, sag limits, creep behavior, and wind loading must be verified. AAAC and ACSR are often selected where higher mechanical performance is required.

Environmental Conditions

Coastal, industrial, and high-pollution environments demand conductors with enhanced corrosion protection. Proper aluminum alloy selection, surface treatment, and hardware compatibility are critical for long service life.

Installation Method

Overhead stringing, underground duct installation, direct burial, and industrial cable tray systems all impose different mechanical and thermal constraints. The correct aluminum cable design ensures safe installation and long-term operational stability.

Manufacturing and Quality Control at HNBF Power

HNBF Power manufactures aluminum cable using advanced stranding lines, precise alloy control, and strict in-process inspection systems. Every conductor is produced in accordance with international utility standards and verified through routine and type testing.

Typical quality controls include:

-

Electrical resistance measurement

-

Tensile strength and elongation testing

-

Dimensional and lay-length verification

-

Surface and strand integrity inspection

This manufacturing discipline ensures consistent performance across large-volume utility projects and long-distance transmission corridors.

Aluminum Cable Applications Across Power Infrastructure

Transmission and Sub-Transmission Lines

High-strength AAAC and ACSR aluminum cables are widely used for 66 kV to extra-high-voltage transmission networks, including renewable energy evacuation lines and grid interconnection projects.

Distribution Networks

AAC and ABC aluminum cables support overhead distribution systems, particularly in urban expansion zones and remote rural electrification programs.

Industrial and Utility Facilities

LV aluminum power cables and concentric cables are deployed in substations, industrial plants, utility service entrances, and infrastructure facilities where reliability and cost control are equally important.

Why Utilities and EPC Contractors Choose HNBF Power

HNBF Power supports utilities, grid operators, and EPC contractors with a complete aluminum cable product portfolio and project-oriented technical support. From conductor design optimization to tender documentation and delivery scheduling, the company helps customers reduce technical risk and improve project execution efficiency.

With global manufacturing capability and experience in large-scale transmission and distribution projects, HNBF Power delivers aluminum cable solutions engineered for real-world grid challenges.

FAQs - Aluminum Cable for Power Projects

1. Is aluminum cable safe for high-voltage transmission lines?

Yes. Properly designed aluminum conductors such as ACSR and AAAC are widely used in high-voltage and extra-high-voltage transmission systems around the world.

2. How does aluminum cable compare with copper cable for utilities?

Aluminum cable is lighter, more economical for large projects, and easier to handle during installation. For most utility transmission and distribution applications, aluminum conductors are the industry standard.

3. Which aluminum cable is best for long spans?

ACSR and high-strength AAAC conductors are preferred for long spans and high mechanical loading conditions due to their superior tensile performance.

4. Can aluminum cable be used in harsh environments?

Yes. With appropriate alloy selection, protective coatings, and compatible fittings, aluminum cable performs reliably in coastal, industrial, and high-pollution environments.

5. Does aluminum cable require special installation practices?

Installers must follow proper tension control, jointing procedures, and connector selection to avoid mechanical damage and ensure long-term electrical performance.

Partner with HNBF Power for Your Aluminum Cable Projects

Whether you are planning a new transmission corridor, upgrading an urban distribution network, or developing an industrial power facility, HNBF Power can provide customized aluminum cable solutions engineered for your project’s electrical, mechanical, and environmental requirements.

Contact HNBF Power today to discuss your technical specifications and receive a tailored aluminum cable solution for your next power infrastructure project.

Categorii

Citeste mai mult

Data Bridge Market Research analyses that the induction cookware market, valued at USD 1.61 billion in 2022, will reach USD 2.64 billion by 2030, growing at a CAGR of 6.4% during the forecast period of 2023 to 2030. The global business landscape is undergoing a transformation, with industries increasingly leaning on deep research and actionable insights to make strategic decisions. One segment...

Executive Summary Protein Powder Market: Growth Trends and Share Breakdown The global protein powder market size was valued at USD 24.24 billion in 2024 and is expected to reach USD 39.23 billion by 2032, at a CAGR of 6.20% during the forecast period Protein Powder Market research report is a verified source of data and information that provides a telescopic view...

Electric Toothbrush Market Overview The global electric toothbrush market size was valued at USD 8.70 billion in 2024 and is projected to reach from USD 10.97 billion in 2025 to USD 70.15 billion by 2033, registering a CAGR of 26.1% during the forecast period (2025-2033). Download Exclusive Research Report PDF Sample: (Including Full TOC, List of Tables...

Executive Summary Anti-Slip Additives Market: Growth Trends and Share Breakdown CAGR Value The global anti-slip additives market size was valued at USD 469.72 million in 2024 and is expected to reach USD 667.99 million by 2032, at a CAGR of 4.50% during the forecast period While preparing this professional and exhaustive Anti-Slip Additives Market research report, customer requirement has...

Stucco Market Overview Global Stucco Market size and share is currently valued at USD 12.13 Billion in 2024 and is anticipated to generate an estimated revenue of USD 17.04 Billion by 2032, according to the latest study by Polaris Market Research. Besides, the report notes that the market exhibits a robust 4.3% Compound Annual Growth Rate (CAGR) over the forecasted timeframe, 2024 -...