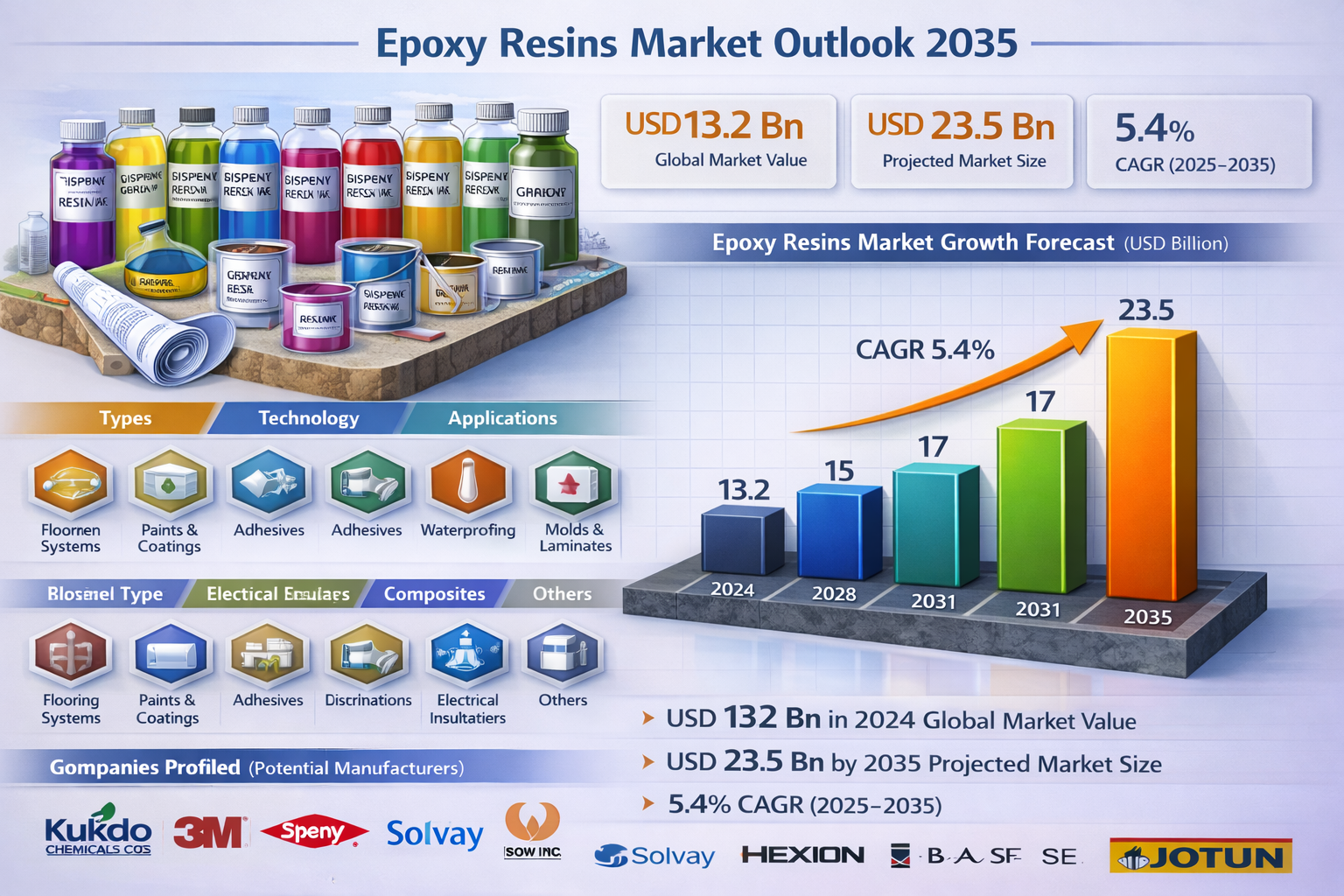

Epoxy Resins Industry to Surpass USD 23.5 Bn by 2035 Amid Rising Industrial Demand

The global epoxy resins market was valued at USD 13.2 Bn in 2024 and is projected to reach USD 23.5 Bn by the end of 2035, expanding at a CAGR of 5.4% from 2025 to 2035. Growth is driven by rising demand from construction, automotive, electrical & electronics, and wind energy sectors. Increasing adoption of lightweight composites, high-performance coatings, and advanced adhesive solutions is further supporting steady market expansion through 2035.

Epoxy resins are thermosetting polymers that exhibit excellent adhesive characteristics, chemical and mechanical properties. Epoxies are thermosetting polymers formed by the reaction between epoxide compounds referred to as curing agents usually amines. These resins are applied widely in construction, electronics, automotive, aerospace, and the marine industry among others. Epoxy resins are popular in coating, adhesive as well as in composite structures that require high strength and durability studies in functional applications.

Dive Deeper into Data: Get Your In-Depth Sample Now! https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=583

Epoxy resins are quite versatile as they have a wide application in bonding, sealing and for protective coatings. They can be used in the construction industry for high-performance floor coatings, adhesives, and repair compounds. They find a wide usage in electronic applications as an insulator and encapsulating layer for parts such as circuit boards.

Market Segmentation

By Service Type

- Custom Formulation: Tailoring resin systems for specific industrial needs (e.g., specialized curing times).

- Distribution & Logistics: Supply chain services ensuring bulk delivery and temperature-controlled storage.

- Technical Support & Consulting: Post-sale services for application troubleshooting and regulatory compliance.

By Sourcing Type

- Petroleum-based (Virgin): Derived from traditional fossil fuel feedstocks like Bisphenol A (BPA) and Epichlorohydrin.

- Bio-based: Sourced from renewable plant oils, tannins, and lignin. This segment is expected to reach a CAGR of 7.2% through 2035.

- Recycled/Modified: Reclaimed resins processed for less critical structural applications.

By Application

- Paints & Coatings: The largest segment, accounting for ~41% of market share.

- Adhesives & Sealants: High-growth area due to the "bonding over bolting" trend in aerospace.

- Composites: Essential for carbon-fiber-reinforced polymers (CFRP).

- Electronic Encapsulation: Protecting delicate circuits in 5G and IoT devices.

By Industry Vertical

- Building & Construction: Flooring, grouts, and structural repairs.

- Automotive: Lightweight parts for EVs and anti-corrosive body coatings.

- Energy: Manufacturing of massive wind turbine blades (reaching 100m+ in length).

- Aerospace & Defense: High-performance structural components.

- Consumer Goods: Sporting equipment like skis, tennis rackets, and bicycles.

Regional Analysis

- Asia-Pacific: The dominant powerhouse, holding nearly 60% of the global market share. Driven by massive industrialization in China, India, and Vietnam.

- North America: Focused on high-value applications in aerospace and defense. The U.S. remains a leader in bio-resins research.

- Europe: The leader in regulatory-driven sustainability, with strict REACH compliance pushing the market toward low-VOC (Volatile Organic Compound) systems.

Market Drivers and Challenges

Drivers

- Renewable Energy Surge: Each wind turbine blade requires thousands of pounds of epoxy-infused composites.

- EV Revolution: Weight reduction is critical for battery range; epoxy composites help shed vehicle weight by up to 30% compared to steel.

- Infrastructure Renovation: Global "Smart City" initiatives utilize epoxy for bridge deck protection and high-durability flooring.

Challenges

- Raw Material Volatility: Fluctuating prices of benzene and propylene impact the cost of BPA and Epichlorohydrin.

- Environmental & Health Concerns: Stricter global regulations on BPA usage and toxic fumes during curing processes.

- Competition from Alternatives: Polyurethanes and polyesters are challenging epoxy in certain low-cost coating applications.

Market Trends

- Sustainable Innovation: Launch of "green" epoxy lines, such as Westlake's EpoVIVET, which focus on lower carbon footprints.

- 3D Printing (Additive Manufacturing): Development of epoxy-based resins for industrial 3D printing of high-strength functional parts.

- Self-Healing Coatings: Integration of micro-capsules that release resin to "heal" scratches in automotive and marine coatings.

Future Outlook

The next decade will see epoxy resins becoming "smarter" and "greener." By 2035, bio-based resins are expected to represent nearly 20% of the total market share. Digital twins and AI-driven manufacturing will optimize resin formulation, reducing waste and ensuring performance consistency across global supply chains.

Key Market Study Points

- High Performance vs. Cost: The primary battleground for manufacturers is maintaining epoxy's superior properties while lowering the "green premium" for bio-based alternatives.

- Supply Chain Resilience: Regionalization of production (shifting away from total reliance on APAC) is becoming a priority for North American and European firms.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=583<ype=S

Competitive Landscape & Recent Developments

The market is consolidated among several global giants and specialized regional players.

Leading Players:

- Hexion Inc. (USA)

- Huntsman Corporation (USA)

- Olin Corporation (USA)

- Kukdo Chemical (South Korea)

- Nan Ya Plastics (Taiwan)

- BASF SE (Germany)

Recent Developments (2024–2025):

- March 2025: Huntsman completed the acquisition of a major logistics-integrated epoxy business to bolster its global distribution.

- August 2024: Hexion launched a new line of fire-retardant resins specifically for high-rise construction safety.

- January 2026: Collaborative research between Dow and Sinopec resulted in a breakthrough "low-temperature cure" resin that reduces energy consumption in manufacturing by 15%.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com