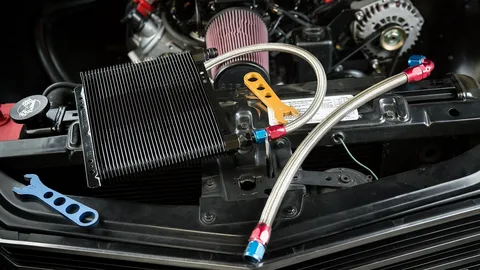

Petroleum engineering tools Cutting-Edge Solutions Enhancing Extraction Efficiency

Petroleum engineering tools encompass a wide range of equipment and technologies used in the exploration and production of oil and gas. These tools are essential for analyzing reservoir conditions, optimizing drilling processes, and improving overall efficiency. The growing focus on sustainable and efficient resource extraction is driving the demand for advanced petroleum engineering tools. Manufacturers are investing in research and development to create innovative solutions that meet the evolving needs of the industry, contributing to the growth of the downhole tools market.

The downhole tools market plays a pivotal role in oil and gas drilling operations, encompassing a variety of instruments used for drilling, evaluation, and production optimization in wellbores. Downhole tools are critical for ensuring drilling efficiency, safety, and resource recovery, enabling operators to reach deeper reservoirs and navigate complex geological formations. Key downhole tools include drill bits, stabilizers, mud motors, packers, and measurement-while-drilling (MWD) instruments. As global energy demand continues to rise, oil and gas companies are investing in technologically advanced downhole tools to enhance well productivity, reduce operational risks, and minimize environmental impact. Modern downhole tools incorporate features such as high-temperature resistance, corrosion protection, and real-time data monitoring to support complex drilling scenarios.

Market Drivers and Trends

Several factors are driving the downhole tools market. The increasing global demand for oil and gas, coupled with exploration in challenging environments such as deepwater, arctic, and unconventional reserves, has fueled the need for advanced downhole solutions. Technological innovation, particularly in smart drilling tools and digital well monitoring, allows operators to optimize drilling performance and reduce non-productive time. The adoption of rotary steerable systems, real-time downhole telemetry, and durable drilling materials has transformed traditional drilling practices, enhancing efficiency and safety. Moreover, the push toward sustainable energy practices has prompted manufacturers to develop environmentally friendly tools that reduce waste, lower energy consumption, and ensure minimal ecological impact during drilling operations.

Segment Analysis

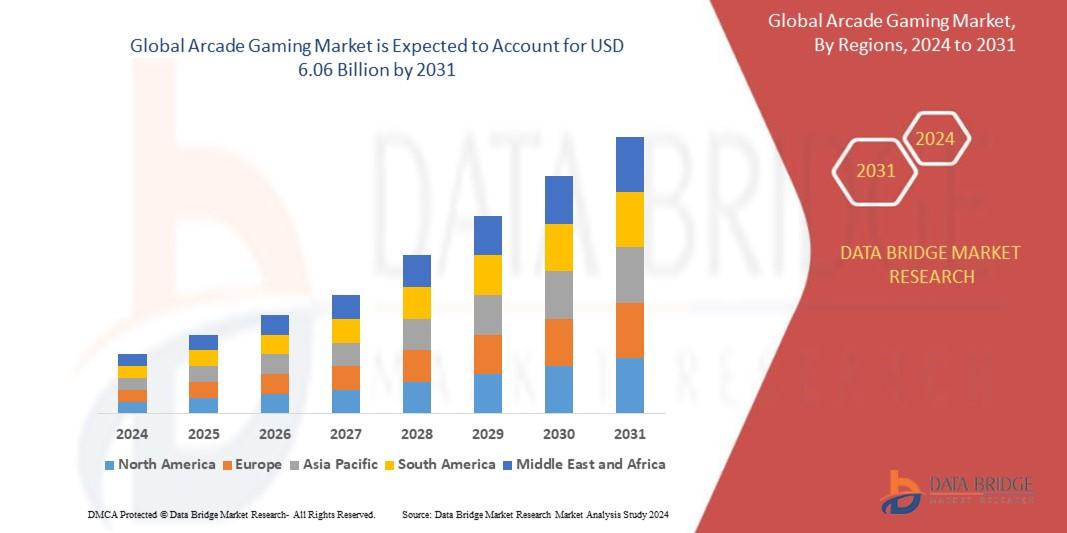

Downhole tools can be segmented based on type, application, and depth of operation. Drill bits and rotary tools are used primarily for drilling and cutting through rock formations, whereas packers and completion tools help isolate and control specific sections of the wellbore. Measurement and evaluation tools, including MWD and logging-while-drilling (LWD) instruments, provide critical real-time data for decision-making during drilling operations. In terms of application, exploration and production, well intervention, and reservoir management are major areas where downhole tools are employed. Geographically, North America and the Middle East dominate the market due to extensive oil and gas reserves and advanced drilling infrastructure, while Asia-Pacific is emerging as a high-growth region due to ongoing energy exploration projects.

Competitive Landscape

The downhole tools market is highly competitive, with established players focusing on product innovation, strategic partnerships, and regional expansion. Companies are investing in research to develop high-performance tools capable of withstanding extreme downhole conditions, such as high pressures, temperatures, and corrosive environments. Additionally, service-oriented strategies, such as providing maintenance contracts, training, and digital support, are helping manufacturers strengthen client relationships. The trend toward integrated drilling solutions, combining multiple downhole tools and monitoring technologies, is redefining market competition, pushing players to offer comprehensive packages that enhance operational efficiency and reduce overall drilling costs.

Challenges and Opportunities

Despite strong growth prospects, the downhole tools market faces challenges such as high capital expenditure, technical complexity, and fluctuating oil prices. The upfront cost of advanced tools and associated maintenance can be a barrier for small and mid-sized operators. Additionally, operating in remote or harsh environments requires specialized skills and equipment. However, these challenges create opportunities for innovation, training programs, and cost-efficient product offerings. The growing focus on digital transformation and predictive analytics presents opportunities to develop smart downhole tools that improve decision-making, reduce downtime, and optimize reservoir extraction. Furthermore, the expansion of offshore and unconventional drilling projects worldwide is expected to drive sustained demand for downhole tools.

Future Outlook

The future of the downhole tools market is promising, with continuous technological advancements shaping its trajectory. Smart tools, real-time monitoring, and automation are expected to dominate industry trends, enabling operators to increase efficiency, safety, and profitability. Integration of AI, machine learning, and IoT in drilling operations will allow for predictive maintenance, reduced operational risks, and enhanced resource recovery. Additionally, growing investments in deepwater, shale, and unconventional drilling projects will sustain demand for specialized downhole tools. As the oil and gas industry navigates energy transition challenges, manufacturers that offer sustainable, high-performance, and cost-effective solutions are likely to capture significant market share globally.

FAQs

Q1: What are the key types of downhole tools?

A1: Key types include drill bits, mud motors, packers, stabilizers, and measurement-while-drilling (MWD) instruments.

Q2: How do downhole tools improve drilling efficiency?

A2: They enhance precision, reduce non-productive time, optimize wellbore stability, and provide real-time operational data.

Q3: Are downhole tools used in unconventional reservoirs?

A3: Yes, advanced downhole tools are critical for unconventional and deepwater reservoirs to navigate complex geological formations safely.

More Related Reports:

Smart Personal Protective Equipment Market

Special Interest Tourism Market